JIAYAO CO., LTD.

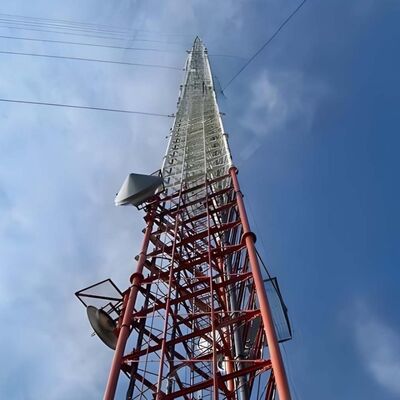

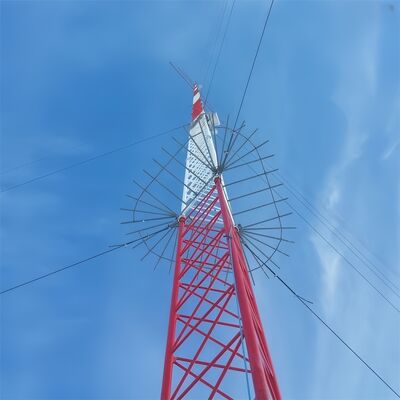

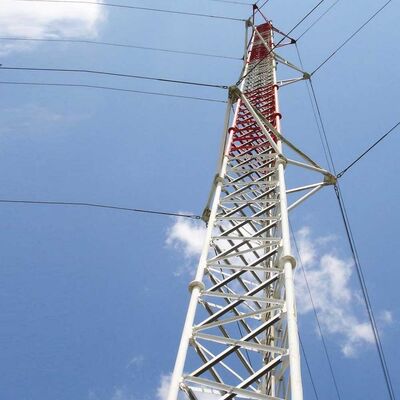

A guyed wire tower (also called a guyed tower) is a tall, slender structure that relies on external guy wires (high-strength steel cables) for stability—unlike self-supporting towers that stand independently. This design lets it reach greater heights with less structural material, making it a cost-effective choice for applications needing extensive coverage or elevation.

1.Specifications

| Design |

| 1. Design Code |

ANSI/TIA-222-G/H/F, EN 1991-1-4 & EN 1993-3-1

|

| Structure Steel |

| 2. Grade |

Mild Steel |

High Tensile Steel |

| GB/T 700:Q235B, Q235C,Q235D |

GB/T1591:Q355B, Q355C,Q355D |

| ASTM A36 |

ASTM A572 Gr50 |

| EN10025: S235JR, S235J0,S235J2 |

EN10025: S355JR, S355J0,S355J2 |

| 3. Design Wind Speed |

Up to 250 km/h |

| 4. Allowable deflection |

0.5 ~1.0 degree @ operational speed |

| 5. Tension strength (Mpa) |

360~510 |

470~630 |

| 6. Yield strength (t≤16mm) (Mpa) |

355 |

235 |

| 7. Elongation (%) |

20 |

24 |

| 8. Impact strength KV (J) |

27(20°C)---Q235B(S235JR) |

27(20°C)---Q345B(S355JR) |

| 27(0°C)---Q235C(S235J0) |

27(0°C)---Q345C(S355J0) |

| 27(-20°C)---Q235D(S235J2) |

27(-20°C)---Q345D(S355J2) |

| Bolts & Nuts |

| 9. Grade |

Grade 4.8, 6.8, 8.8 |

| 10. Standards for mechanical properties |

| 10.1 Bolts |

ISO 898-1 |

| 10.2 Nuts |

ISO 898-2 |

| 10.3 Washers |

ISO 6507-1 |

| 11. Standards for Dimensions |

| 11.1 Bolts |

DIN7990, DIN931, DIN933 |

| 11.2 Nuts |

ISO4032, ISO4034 |

| 11.3 Washers |

DIN7989, DIN127B, ISO7091 |

| Welding |

| 12. Method |

CO2 Shielded Arc Welding & Submerged Arc Welding(SAW) |

| 13. Standard |

AWS D1.1 |

| Marking |

| 14. Method of marking of the members |

Hydraulic Press Stamping |

| Galvanizing |

| 15. Galvanization standard of steel sections |

ISO 1461 or ASTM A123 |

| 16. Galvanization standard of bolts and nuts |

ISO 1461 or ASTM A153 |

What is the tower boday of guyed wire tower?

The tower body of a guyed wire tower (guyed mast tower) is the central, slender load-bearing structure that supports antennas, sensors, or other equipment, relying on external guy wires for lateral stability (rather than self-supporting rigidity). Typically constructed as a tubular or lattice steel framework, it is narrower than self-supporting towers and features a tapered design (wider at the base, narrower at the top) to optimize load distribution and wind resistance. The tower body is fabricated from galvanized structural steel (complying with ASTM A36/S235JR standards) to ensure corrosion resistance and long-term durability in outdoor environments. It serves as the mounting base for key accessories such as climbing ladders, antenna mounts, and cable trays, and its modular design allows for customization of heights ranging from 30m to over 200m, tailored to applications like broadcasting, telecom, or meteorological monitoring.

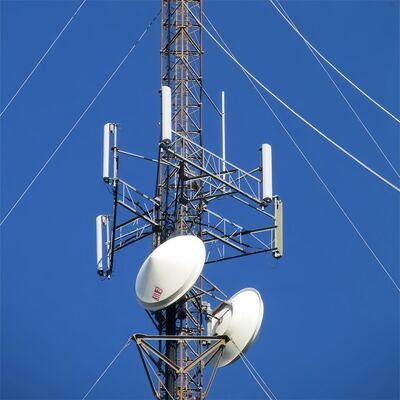

How to mount antenna on the guyed wire tower?

Mounting an antenna on a guyed wire tower follows a structured, safety-compliant process aligned with the tower’s design and industry standards:

- Pre-installation Preparation: Verify the tower’s load-bearing capacity to ensure it can support the antenna’s weight (including hardware and associated cables). Inspect the tower body for corrosion, structural damage, or loose connections, and confirm compliance with local safety codes (e.g., IEC 62305 for lightning protection).

- Antenna Mount Installation: Attach dedicated antenna mounts (integrated accessories of the tower) to pre-designated points on the tower body. These mounts are typically secured using high-strength bolts compatible with the tower’s galvanized steel structure, ensuring a firm connection that withstands wind forces and vibrations.

- Antenna Lifting & Positioning: Use cranes or specialized lifting equipment to hoist the antenna to the target height (strategically chosen for optimal signal coverage). Align the antenna with the intended transmission/reception direction, using laser tools or alignment meters for precision.

- Securing the Antenna: Fasten the antenna to the pre-installed mounts using compatible hardware, tightening bolts to the specified torque to prevent movement. Ensure the antenna is level and stable, with no wobble that could affect performance or structural integrity.

- Cable Routing & Integration: Route signal cables or feeders through the tower’s integrated cable trays to protect them from environmental damage. Connect the cables to the antenna and run them down to ground-based equipment, ensuring proper insulation and waterproofing at connection points.

- Final Inspection: Conduct a visual check of the antenna, mounts, and cables to confirm secure installation. Test the antenna’s signal transmission/reception to verify functionality, and ensure all safety protocols (e.g., fall protection for workers) are followed throughout the process.

What is the Anti Climbing Device on the guyed wire tower?

Anti-climbing device for a guyed wire tower is a specialized safety component installed on the tower body to prevent unauthorized access and reduce fall risks. Common designs include:

- Anti-climb collars/skirts: Circular or conical steel barriers mounted near the base of the tower (typically 2–3m above the ground) to block climbing attempts by denying handholds or footholds.

- Spiked or jagged deterrents: Non-lethal, pointed steel attachments on lower tower sections or ladders to discourage unauthorized climbing.

- Locked access: If the tower is equipped with a ground-level access panel or ladder entry point, a locked gate restricts access to certified personnel only.

These devices are constructed from corrosion-resistant materials (e.g., galvanized steel, matching the tower body) to withstand outdoor conditions. Their primary purpose is to enhance safety by preventing accidental or intentional climbing by untrained individuals, aligning with local building safety codes and liability mitigation for tower operators.

How to connect guyed wire and guyed wire tower?

Connecting guy wires to a guyed wire tower involves a secure, load-bearing process to ensure the wires can effectively stabilize the tower against wind and seismic forces:

- Preparation: Select guy wires made of high-tensile steel cables (complying with ASTM A475) with zinc or polymer coatings for durability. Ensure the tower body has pre-fabricated attachment points (e.g., lugs, brackets, or crossarms) at 20–30m intervals, as specified in the tower’s design.

- Attachment Hardware Installation: Mount heavy-duty guy wire brackets or clevises to the tower’s pre-designated attachment points using high-strength bolts (compatible with the tower’s galvanized steel structure). These brackets are engineered to distribute tension evenly across the tower body.

- Wire Termination: Use professional termination fittings (e.g., swage sleeves, cable clamps, or thimbles) to secure the end of each guy wire. Swage sleeves are crimped onto the wire for a permanent, high-strength connection, while cable clamps provide adjustable tensioning.

- Connection & Tensioning: Attach the terminated end of the guy wire to the tower’s bracket using a shackle or pin, ensuring a secure fit with no slack. Use a tensioning tool (e.g., a turnbuckle or come-along) to adjust the wire’s tension to the design specification—critical for balancing lateral forces on the tower.

- Verification: Check that the connection is aligned with the tower’s tapered structure and that the wire is tensioned uniformly (avoiding over-tightening, which could stress the tower body). Confirm the hardware and termination fittings are corrosion-resistant and comply with the tower’s safety standards.

How to connect guyed wire and guyed anchor bolt?

Connecting guy wires to guyed anchor bolts (ground anchors) is a critical step to transfer the wire’s tension to the ground, ensuring the tower’s stability:

- Anchor Preparation: Ensure the ground anchor (heavy-duty concrete or steel anchor, designed for tension loads) is properly installed in the ground at a 45–60° angle relative to the guy wire. The anchor must be fully cured (for concrete) and securely embedded to resist pull-out forces.

- Anchor Bolt Exposure: Ensure the anchor’s top bolt (guyed anchor bolt) is protruding above the ground and threaded to accommodate connection hardware. The bolt should be made of high-strength steel to withstand the tension of the guy wire.

- Wire Termination: Terminate the free end of the guy wire using the same high-strength fittings (swage sleeves, cable clamps, or thimbles) used for the tower connection, ensuring a secure, load-bearing end.

- Connection Hardware Assembly: Attach a turnbuckle (for tension adjustment) and a shackle to the terminated guy wire. The turnbuckle connects to the guyed anchor bolt via a nut or washer, allowing for fine-tuning of the wire’s tension.

- Tensioning & Securing: Use the turnbuckle to tension the guy wire to the required specification, ensuring it resists lateral forces without pulling the anchor. Once tensioned, lock the turnbuckle with cotter pins or lock nuts to prevent loosening over time.

- Final Check: Verify that the connection is secure, the anchor shows no signs of movement, and the guy wire is aligned at the correct 45–60° angle. Inspect for corrosion on the bolt, hardware, and wire termination, ensuring compliance with IEC 62305 and local safety codes.

Please Click Here For More Information!!!!!!

3.Cooperation Customers

4.Certifications

5.Our Services

JIAYAO CO., LTD. is a professional telecom tower manufacturer and approved by ISO9001. We are committed to providing customers with the most optimized solutions and the best communication tower. Many products have been exported to USA, Europe and other 55 different counties.

We specialize in designing and manufacturer of angle steel tower, tube steel tower, monopole tower, pine tree tower, guyed tower and guard tower. Our departments include design, R&D, inspection, laboratory, QC, galvanization and steel tower departments. Our raw materials come from famous steel mills in China: HBIS Group, Baowu Steel Group, Shougang Group.

If you need it, we will welcome you 24 hours a day!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Παρακαλούμε ελέγξτε το email σας!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Παρακαλούμε ελέγξτε το email σας!